|

| This is what Alumilite looks like from the end |

|

| I cut the Alumilite with a fine tooth blade in a jigsaw |

|

| Then I held it back up to the spoiler and put blocks under it to keep it level |

|

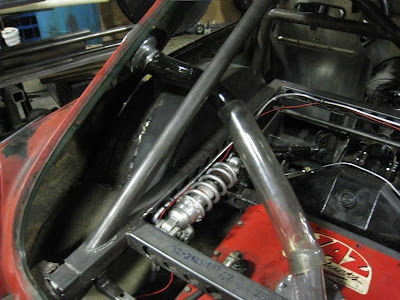

| These two brackets for the air dam had to be modified so I could bolt the splitter to the air dam mount |

|

| Here it is bolted to the top of the air dam mount |

|

| Everything bolted back up. |

|

| I still have to add some adjustable struts and the edges could be changed because we still have to add fender flares. |